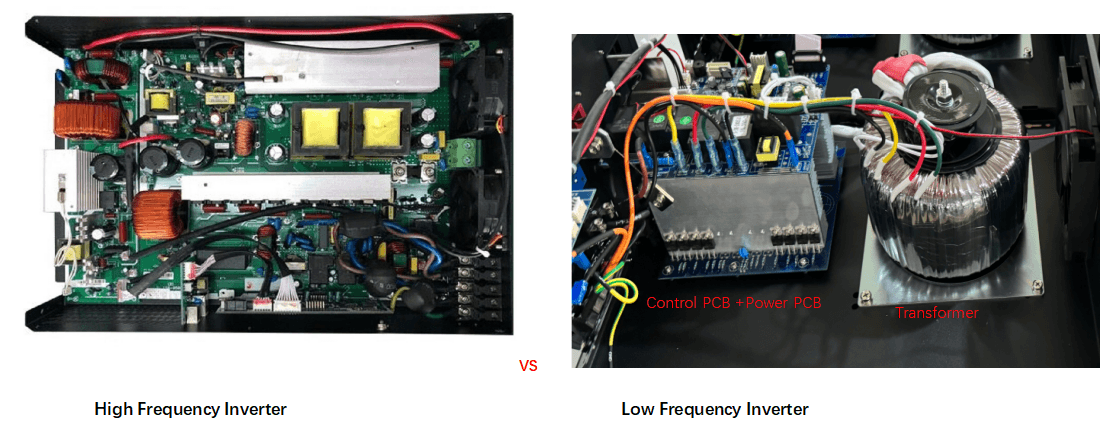

In-depth comparison of low-frequency vs high-frequency inverters: Why Frequency Inverters Are More Suitable for Off-Grid Applications?

In the application of off-grid solar energy systems, the inverter is of the core of the entire system. Common inverters on the market are divided into power frequency inverters and high frequency inverters. For importers, how to choose the right inverter is crucial to ensure product stability and user experience. This article will make an in-depth comparison of three aspects: impact resistance, performance with inductive loads, and service life, to help you make better purchasing decisions.

- Impact resistance comparison

The power frequency inverter has a strong impact resistance due to the use of a large-capacity power frequency transformer, which can easily cope with the current shock generated by the start-up of a high-power load. For example, when an inductive load such as a water pump or motor is started, the current may instantly reach 3-7 times the rated current. Due to the energy storage characteristics of the transformer, the power frequency inverter can effectively absorb and buffer these shocks to ensure stable operation of the system.

In contrast, the high-frequency inverter has a weaker impact resistance due to the lack of a power frequency transformer. When the load starts instantly, it is easy for the inverter protection to trip or the equipment to fail to start. This characteristic makes high-frequency inverters perform poorly in off-grid systems with more inductive loads.

- Performance with inductive loads

In off-grid systems, inductive loads such as water pumps, motors, and air conditioners are common equipment. With excellent output waveforms and stable voltage control capabilities, power frequency inverters can provide stable power support for these inductive loads to avoid damage to the equipment due to startup shock.

However, high-frequency inverters are prone to waveform distortion, voltage fluctuations, and other problems when carrying inductive loads, causing the equipment to fail to work properly or shorten its life. Especially in rural and remote areas where the power grid is unstable or completely off-grid, power frequency inverters perform more reliably.

The transformer design of the power frequency inverter makes it particularly suitable for driving:

Water pumps (especially deep well pumps)

Air conditioning compressors

Electric tools

Refrigeration equipment

Key indicators comparison:

| Waveform distortion rate: | Power frequency: <3% | High frequency: 5-8% |

| Motor start success rate: | Power frequency: 98% | High frequency: 82%

|

| Long-term operation temperature | rise Power frequency: <30°C | High frequency: >50°C

|

⚠️Procurement warning: If your customer’s application scenario includes motor loads, high-frequency inverters may cause frequent failures and complaints.

- Service life comparison

The design life of the power frequency inverter is generally 10-15 years or even longer, mainly relying on the high reliability and durability of core components such as transformers. Even when operating in harsh environments, its stable structure can ensure long-term stable power supply.

Relatively speaking, high-frequency inverters have more electronic components, poor impact resistance, and faster component aging. The service life is usually 5-8 years, and it is more susceptible to environmental factors. Therefore, from the perspective of long-term investment, power frequency inverters are more cost-effective.

Service life: 5-7 years longer for power frequency inverters

We tracked and counted the inverters shipped from 2010 to 2015:

Years Low frequency inverter repair rate High frequency inverter repair rate

| Year | Low frequency | High frequency |

| Year 3 | 0.8% | 5.2% |

| Year 5 | 2.1% | 18.7% |

| Year 8 | 4.3% | Obsolete |

The fundamental reason for the difference in service life:

- Power frequency transformers are resistant to aging, and high frequency electronic components are prone to degradation

- Power frequency has a large design margin, and high frequency operates at full load for a long time

- Power frequency has better heat dissipation, and components such as capacitors have a low operating temperature

Comparison of the core technologies of power frequency and high frequency inverters

| Comparison dimensions | Low-frequency inverter | High-frequency inverter |

| Working principle | Transformer isolation | Electronic circuit conversion |

| Weight | Heavy (including transformer) | Lightweight |

| Efficiency | 90-93% | 94-97% |

| Manufacturing cost | High | Low |

| Peak withstand capacity | 300% rated power for 5-8 seconds | 150% rated power for 3 seconds |

| Typical life | 10-15 years | 5-8 years |

Selection suggestions for importers

Although the initial cost of industrial frequency inverters is 20-30% higher, it is more economical after considering the following factors:

1) After-sales cost reduction of more than 60%

2) Repeat orders due to improved customer satisfaction

3) Accumulation of brand reputation

Suitable scenarios for choosing industrial frequency inverters:

✔️ Inductive loads such as motors and compressors

✔️ Remote areas with poor grid quality

✔️ Commercial applications with high reliability requirements

✔️ Importers who want to establish a long-term brand image

Applicable scenarios for high-frequency inverters:

➤ Purely resistive loads (such as lighting, TV)

➤ Weight-sensitive mobile applications

➤ Short-term projects with extremely limited budgets

Frequently Asked Questions

Q: Does the low efficiency of industrial frequency inverters mean more power consumption?

A: The actual difference is only 3-5%, but the power generation of industrial frequency inverters is higher in harsh environments (not easy to protect shutdown)

Q: How to explain the price difference to end customers?

A: Use the TCO (total cost of ownership) calculator to show the maintenance and replacement costs saved in 5 years

Q: Which brands of power frequency inverters are the most reliable?

A: Pay attention to whether the following are used:

1) Whether the field effect/IGBT and core components use internationally renowned brands

2) Whether the winding transformer has sufficient power

3) Whether there is a warranty

Quality determines long-term profits

In the off-grid solar market, customers will eventually pay for reliability. Our tracking data shows that importers who insist on selling power frequency inverters have a 47% higher customer retention rate in 5 years. Your selection decision today will determine your reputation and position in the market in the future.

- Conclusion

In summary, power frequency inverters have become the only choice for off-grid solar systems with their excellent impact resistance, stable inductive load support and ultra-long service life. Especially in remote and unstable power grid areas, their performance advantages are particularly prominent.

For importers, choosing power frequency inverters can not only effectively reduce maintenance costs but also provide customers with more reliable power supply solutions. This is the fundamental reason why more and more off-grid application scenarios choose power frequency inverters.

If you are looking for high-quality power frequency off-grid inverters, please contact Swina. We will provide you with the most competitive products and professional support to help you stand out in the market.

Welcome to contact us:

① Request the “Power Frequency Inverter Selection Manual”

② Make an appointment for an engineer video conference to analyze your specific market needs

③ Apply for a prototype for field testing