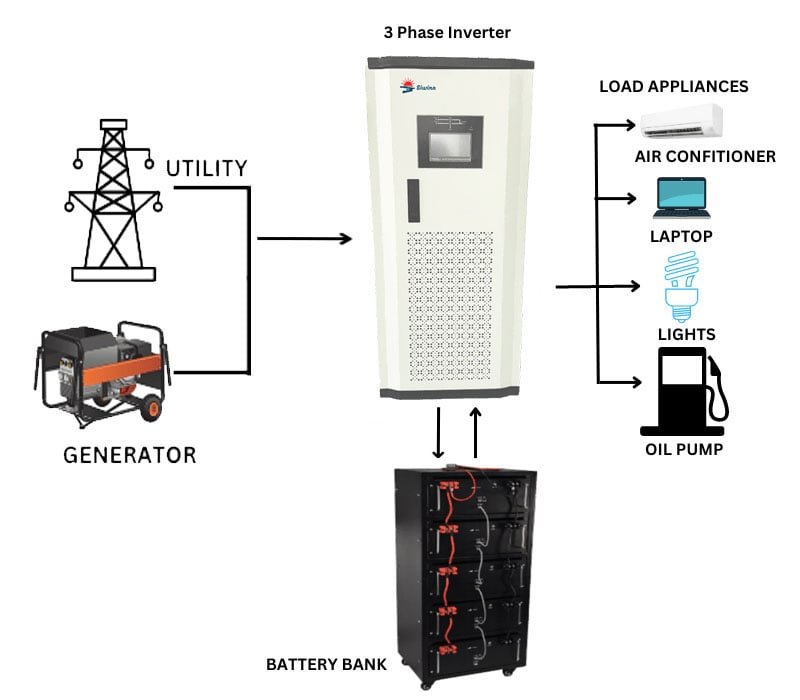

three-phase solar inverters are Perfect for off-grid use in factories, Data Centers, and Large-Scale Commercial Buildings operations in mining, oil and gas, and construction sectors., are engineered to provide reliable, efficient, and high-quality power solutions for demanding applications. With a combination of advanced technology, robust protection features, and user-friendly interfaces, our inverters ensure optimal performance and uninterrupted power supply.

| AC input | 380VAC or 220VAC |

|---|---|

| color | White/blue/Green/orange |

| AC output | 380VAC or 220VAC |

| DC Voltage(Battery ) | 192VDC or 384VDC |

Introduction to High-Capacity three phase solar Inverters

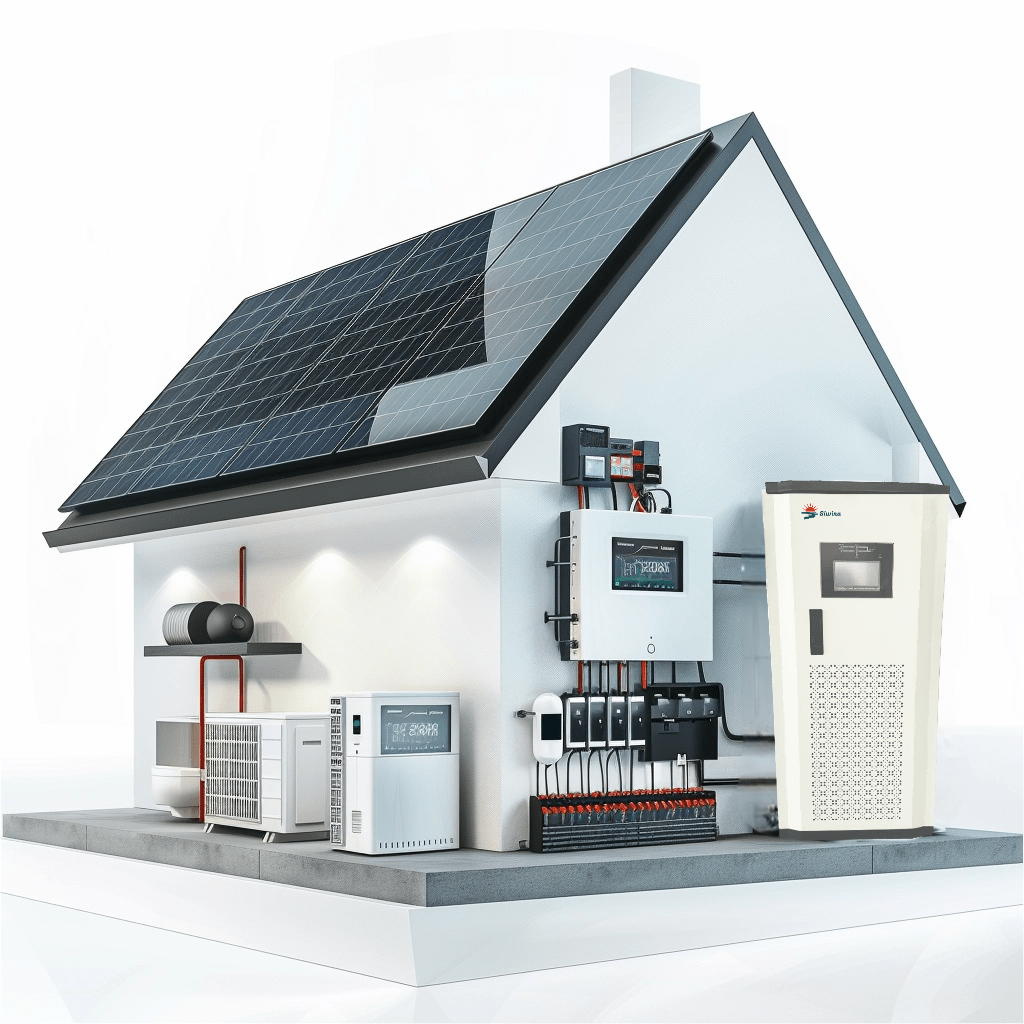

High-capacity three inverters are essential components in modern power management systems, offering a robust solution for diverse energy requirements. These three phase inverters come in a variety of power capacities, including 20KW 30KW 40KW 50KW 60kW 80kW 100kW 150kW, and 200kW, making them highly versatile and adaptable to a wide range of applications. Whether deployed in factories, offices, supermarkets, or large residential homes, these inverters ensure a stable and efficient power supply, which is crucial for maintaining operational continuity and minimizing downtime.

Technical Data Sheet:

| MODEL | 30KW | 40KW | 50KW | SWN-80KVA | SWN-100KVA | SWN-150KVA | SWN-200KVA | SWN-250KVA | |

|---|---|---|---|---|---|---|---|---|---|

| Power | 30KW | 40KW | 50KW | 60KW | 80KW | 120KW | 160KW | 200KW | |

| Power Factor | 1 | ||||||||

| Input | Phase | 3 phase 4 wire and ground | |||||||

| Voltage Range | 380VAC± 20%(3 phase), phase voltage 220V or 208V± 20%(3 phase), phase voltage 127V | ||||||||

| Frequency Range | 45 – 65Hz | ||||||||

| Rectifier | 3 phase 6 pulses, 12 pulses is optional | ||||||||

| Output | Phase | 3 phase 4 wire and ground | |||||||

| Wave form | Pure sine wave | ||||||||

| Crest Factor | 3:01 | ||||||||

| Rated voltage | 208VAC + -1% for static load, 5% forfluctuant load | ||||||||

| Phase voltage setting | 192V -270V or 105- 138VAC, pls confirm when order | ||||||||

| Transient response | +/-5%, 10ms | ||||||||

| Frequency | 50 / 60 Hz + / - 0.05% | ||||||||

| Total-harmonic distortion | < 3% linear load, < 5%( nonlinear load) | ||||||||

| Short circuit current | Short current for 0.1s (200% current) | ||||||||

| Overload capacity | Overload 125% for 10 Mins, 125%-150% for 1min. automatically resume when load become normal | ||||||||

| Battery | Battery | Maintenance free lead-acid cell | |||||||

| DC Voltage | 192VDC or 384VDC | 384VDC | |||||||

| Max Charge Current | 10-20A | ||||||||

| Bypass | Type | Static state + manual maintenance bypass | |||||||

| Input Phase | 3 phase 4 wire and ground | ||||||||

| Input voltage range | 15% - 25% (the front control panel selectable) | ||||||||

| Transfer time | Inverter / bypass transfer switch time(Overload): 0ms inverter / bypass transfer switch time (fault inverter) 1ms | ||||||||

| Efficiency | Whole unit | > 85% | |||||||

| Inverter | 93 | ||||||||

| Remote signaling | Dry contact (battery low, battery discharging, bypass/ fault); output 12Vdc/80mA, Optional parts | ||||||||

| Communication interface | RS232 ( SNMP, modem optional ) | ||||||||

| Running temperature | 0-40 degree Celsius | ||||||||

| Relative Humidity | Less than 95% (without condensing) | ||||||||

| Noise at 1 M | less than 60 dB | ||||||||

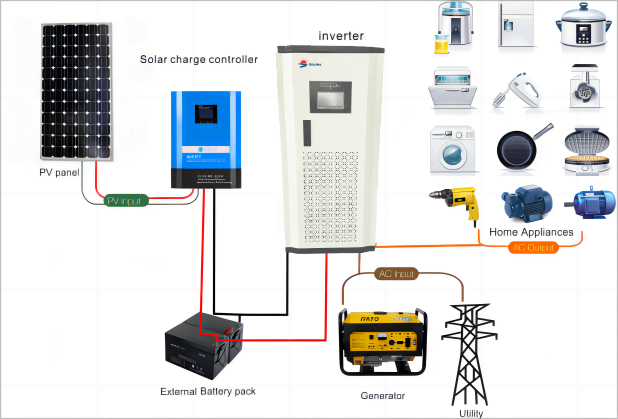

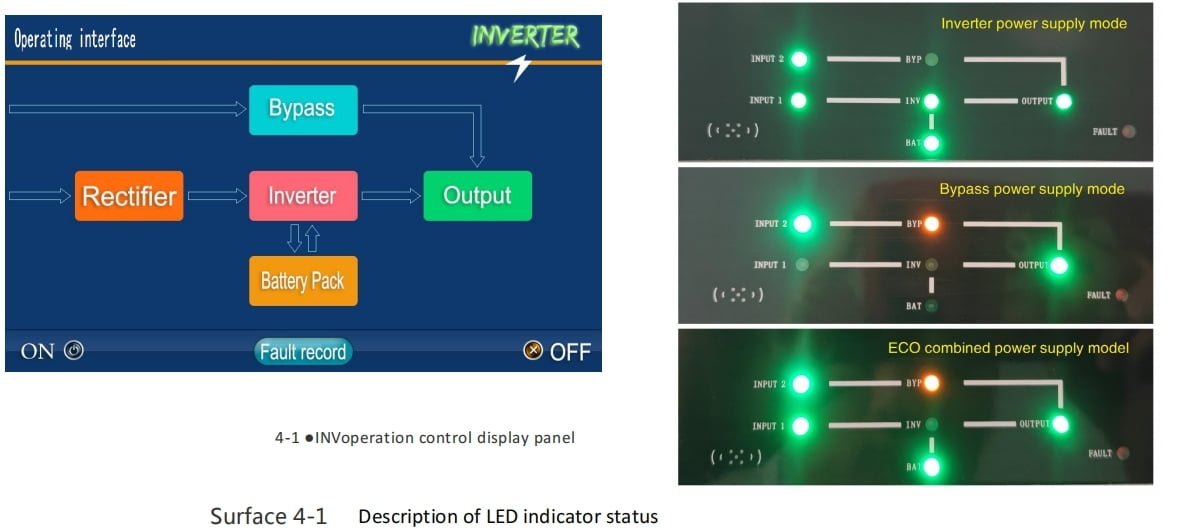

Inverter working mode and connection diagram

1. Battery Priority Mode (Off-Grid Mode for solar power system)

First Priority on Battery Power: In off-grid scenarios, our inverter prioritizes battery power to supply AC loads. Ideal for locations without a utility grid, such as remote solar power systems.

Efficient Battery Usage: Continues drawing power from the battery bank until reaching a predefined minimum state of charge. Non-critical loads are automatically shut off to conserve battery life for essential equipment.

Optimized for Solar Power: In events like nightfall or low solar output, the system relies solely on battery power. If integrated, a backup generator can be automatically activated to ensure continuous operation.

2. Utility Grid Priority Mode (Backup Mode)

First Priority on Grid Power: In backup mode, the inverter draws AC power from the utility grid first, reserving battery power for outages. This prevents unnecessary battery drain when the grid is stable.

Automatic Battery Charging: When connected to the grid, the inverter charges the battery bank using solar power or other available sources, maintaining optimal battery levels for backup use.

Seamless Transition: On loss of grid power, the inverter instantly switches to battery mode with minimal disruption, ensuring uninterrupted power supply to both critical and non-critical loads. A backup generator can be set to start automatically to either continue powering loads or recharge batteries.

Key Features of Our Inverters

Our high-capacity industrial inverters are designed to meet the rigorous demands of modern industrial applications. One of the standout features is the super wide input voltage range, accommodating voltages from 285V to 475V. This extensive range ensures that the inverters can handle fluctuating power supplies without compromising performance, providing robust operation even in challenging electrical environments.

Additionally, the integrated Uninterruptible Power Supply (UPS) function enhances operational efficiency and assures continuous power delivery during outages. This feature is crucial for industries where power consistency is non-negotiable, preventing data loss and downtime.

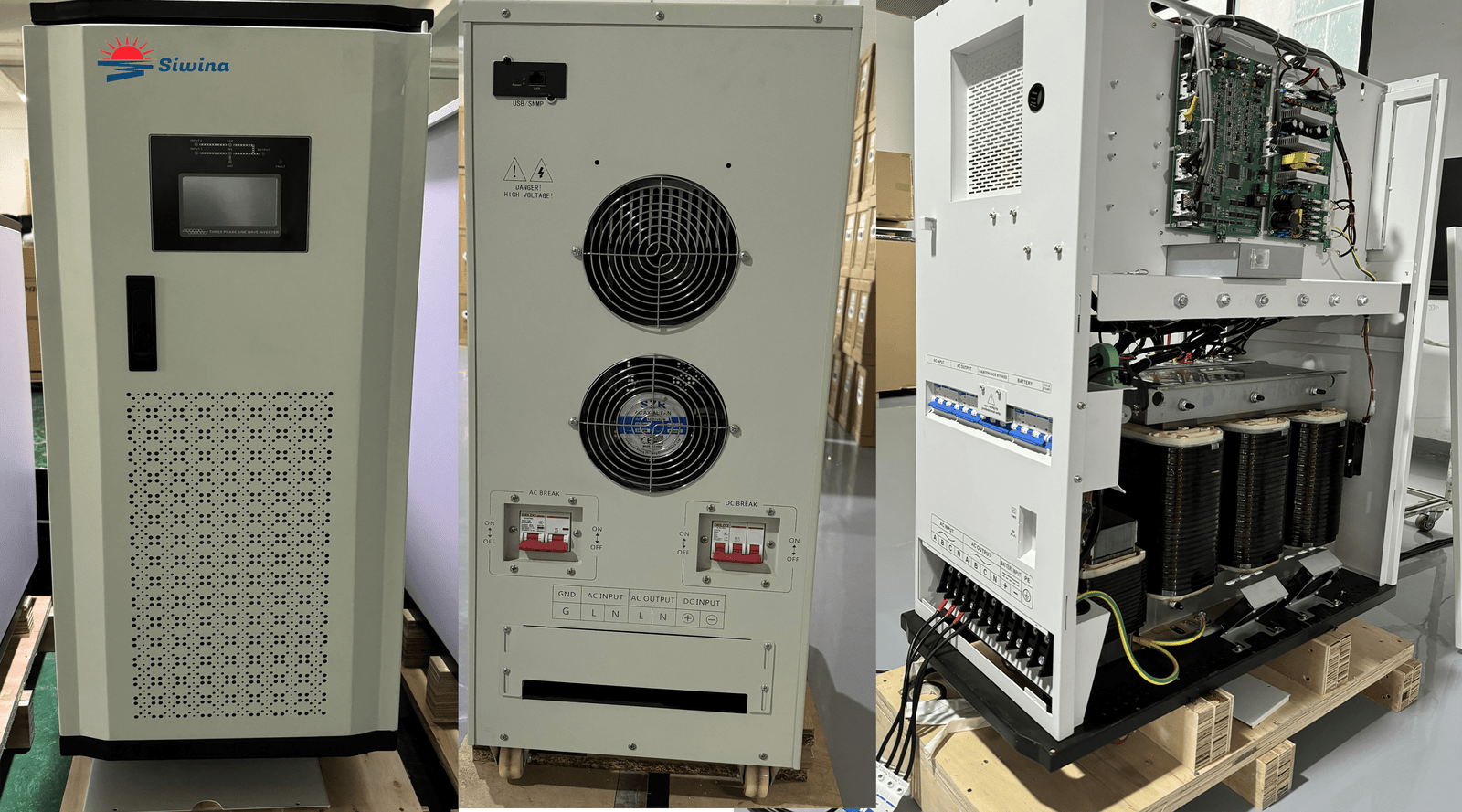

The high-quality touch LCD display is another significant feature, offering intuitive and user-friendly control. The display provides real-time monitoring of the inverter’s status, simplifying diagnostics and maintenance. This ease of interaction ensures that operators can swiftly address any issues, thereby minimizing downtime.

Advanced microcomputer control technology underpins the reliability and precision of our inverters. This technology enables sophisticated management of power conversion processes, ensuring optimal performance and efficiency. The microcomputer’s capability to execute complex algorithms allows for seamless integration with various industrial systems.

Comprehensive protection mechanisms are embedded within our inverters to safeguard against potential risks such as overvoltage, undervoltage, overload, short circuits, and overheating. These protective features extend the lifespan of the inverters and provide peace of mind to users by preventing damage to connected equipment.

The pure sine wave output, achieved through advanced Pulse Width Modulation (PWM) and Sinusoidal Pulse Width Modulation (SPWM) technology, ensures that the power supplied is clean and stable. This is particularly important for sensitive industrial equipment that requires a steady and reliable power source.

Our inverters also boast robust impact resistance, making them suitable for harsh industrial environments. The construction materials and design enhancements ensure that the inverters can withstand physical shocks and vibrations, maintaining their integrity and functionality over time.

Lastly, the simplicity of the wiring and installation process cannot be overstated. Designed with user convenience in mind, the straightforward installation reduces setup time and labor costs, enhancing overall operational efficiency. The ease of installation ensures that businesses can quickly deploy and integrate the inverters into their existing systems, resulting in minimal disruption and swift operational readiness.

Where are three-phase solar inverters mainly used?

Applications and Use Cases

High-capacity industrial inverters play a crucial role across a spectrum of applications, ensuring a reliable and stable power supply in various settings. These versatile devices are employed to meet the demanding power needs of factories, offices, supermarkets, and large residential homes, showcasing their adaptability.

Factories

In industrial environments, high-capacity inverters are indispensable for maintaining continuous machinery operation. Factories rely on these inverters to provide stable power to critical equipment, minimizing downtime and enhancing productivity. For instance, automated assembly lines, CNC machines, and other industrial equipment require a consistent power supply to function efficiently, and high-capacity inverters ensure this continuity.

Offices

In office settings, high-capacity inverters are essential for delivering stable power to critical equipment. These devices support uninterrupted operation of servers, communication systems, and other office technology, preventing data loss and ensuring smooth business operations. By maintaining a steady power supply, high-capacity inverters help offices avoid disruptions that could impact productivity and client services.

Supermarkets

Supermarkets depend on high-capacity inverters to keep essential systems operational, particularly refrigeration units that preserve perishable goods. These inverters provide a reliable power source to maintain the correct temperatures, ensuring food safety and reducing spoilage. Additionally, inverters support other critical systems such as lighting and point-of-sale terminals, contributing to a seamless shopping experience for customers.

Large Residential Homes

In large residential homes, high-capacity inverters offer reliable power to HVAC systems, security systems, and home automation. These inverters ensure that heating, cooling, and security systems operate without interruption, even during power outages. Homeowners can also rely on inverters to power smart home devices, maintaining the convenience and functionality of their automated systems.

Overall, the versatility and adaptability of high-capacity industrial inverters make them an essential component in various settings. Whether in factories, offices, supermarkets, or large residential homes, these inverters provide reliable and stable power, meeting diverse power needs efficiently.

What are the advantages of three-phase solar inverters and what are the benefits to the load?

Technical Specifications and Conclusion

High-capacity industrial inverters are engineered to meet stringent performance requirements. These inverters typically offer a power capacity ranging from 10 kVA to several megawatts, making them suitable for a diverse array of industrial applications. The input voltage range is commonly between 400V and 800V DC, which ensures compatibility with various power sources. On the output side, these inverters provide a stable and consistent AC voltage of 230V or 400V, depending on the specific model and application needs.

One of the standout features of these inverters is their advanced display systems. Most units are equipped with touch-screen interfaces that provide comprehensive real-time data, including input/output voltage, current status, and fault diagnostics. This facilitates easier monitoring and management of the inverter’s performance, thus enhancing operational efficiency.

Control systems in high-capacity inverters are often based on sophisticated microprocessor or DSP (Digital Signal Processing) technology. This enables precise control over the power conversion process, ensuring optimal efficiency and reliability. Protection features are another critical aspect; these inverters are equipped with multiple layers of protection, including over-voltage, under-voltage, over-temperature, and short-circuit protections. Such robust protective mechanisms ensure long-term durability and safety.

The output waveform of high-capacity industrial inverters is generally a pure sine wave, which is crucial for the proper functioning of sensitive industrial equipment. Pure sine wave output minimizes harmonic distortion, leading to better performance and longevity of connected devices.

In summary, high-capacity industrial inverters stand out due to their reliability, efficiency, and high-quality power output. Their technical specifications make them ideal for a range of applications across industrial, commercial, and even residential sectors. By ensuring consistent and high-quality power delivery, these inverters play a pivotal role in enhancing energy reliability and operational efficiency, making them an indispensable component in modern energy management systems.

FAQ

Q1: Can I have a sample/trial order for a test?

A: Yes, we accept sample orders/trial orders for testing. You can experience the quality and performance of our products before making a larger investment.

Q2: When will you deliver the goods?

A: For sample orders, we typically deliver within 3-5 working days. For quantity orders, it may take 7-15 working days after receiving the deposit payment. We strive to deliver your order promptly and efficiently.

Q3: Do you offer a guarantee for your solar products?

A: Yes, we offer an 18-month guarantee for our inverters and inverter-related products, including solar generators and solar inverters.

Q4: Can you do OEM/ODM?

A: Yes, we accept OEM/ODM orders for power inverters, solar inverters, Hybrid inverter ,MPPT solar controllers, solar generators. Simply send us your detailed request, and our sales specialist will provide you with the best quote tailored to your needs.