Why Transformer-Based Low-Frequency Inverters Are the Smart Choice for Inductive Loads

Meta Title:

Transformer-Based Low-Frequency Inverters for Inductive Loads | SWN Inverter

Meta Description (≤160 chars):

Discover why low-frequency inverters with transformers are ideal for inductive loads like pumps and motors—longer life, better surge, more stability.

🔋 Introduction

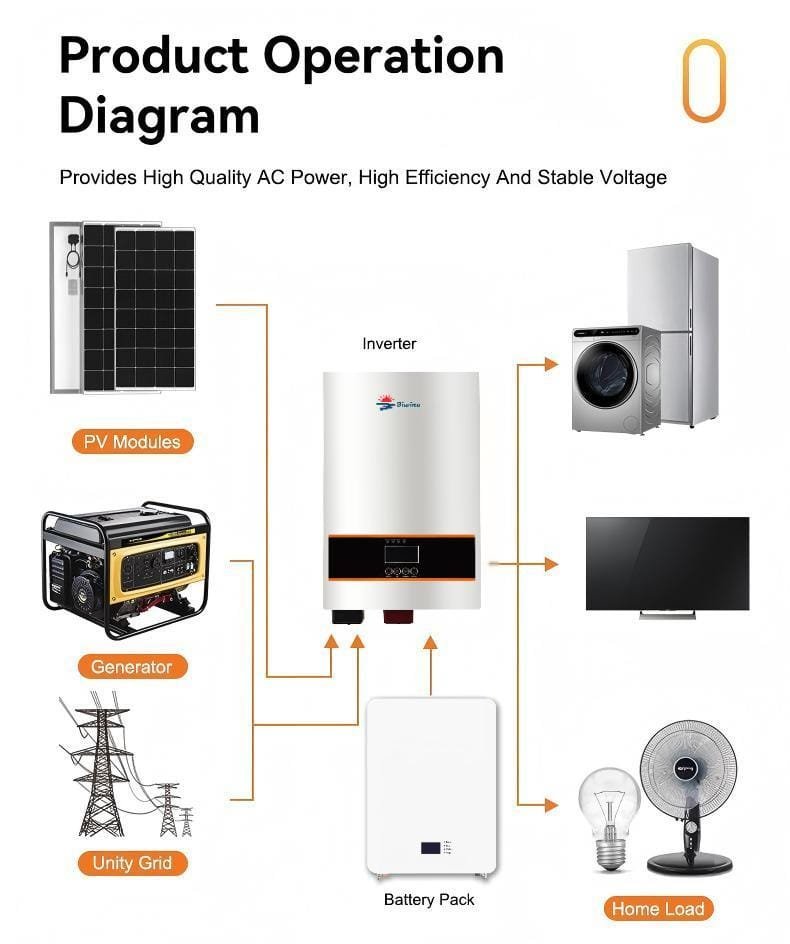

Off-grid solar systems often face one major technical challenge: powering inductive loads such as water pumps, refrigerators, compressors, and electric motors. These devices demand high surge power and voltage stability, especially at startup. In this context, transformer-based low-frequency inverters consistently outperform their high-frequency counterparts—making them a superior choice for importers and solar integrators serving heavy-duty applications.

⚙️ What Is a Transformer-Based Low-Frequency Inverter?

Unlike high-frequency inverters that rely on compact high-speed circuits, low-frequency inverters use a large toroidal transformer to convert DC into pure sine wave AC output. This traditional approach may be bulkier, but it offers significantly better performance and protection, especially for demanding loads.

🚀 Advantage 1: Superior Surge Handling for Inductive Loads

Inductive loads require a 2–7x surge current during startup. A small pump motor rated at 1.5kW may demand over 4.5kW momentarily when starting.

✅ Low-frequency inverters can deliver 200–300% surge capacity for several seconds.

❌ High-frequency inverters often trip or shut down when faced with such loads.

Real-world Example:

In a Nigerian off-grid farm, high-frequency inverters frequently failed to start irrigation pumps. After switching to SWN’s transformer-based low-frequency model, performance became stable and uninterrupted.

💡 Advantage 2: More Stable Performance in Harsh Conditions

Transformer-based inverters handle power fluctuations and load shocks with ease. They:

Maintain voltage quality under load

Operate reliably under high temperature and humidity

Are less sensitive to poor battery conditions or grid noise

This makes them ideal for off-grid regions in Africa, South Asia, and the Middle East—where power environments are often unpredictable.

🔧 Advantage 3: Longer Operational Lifespan

Because of their simple yet durable internal structure, transformer-based inverters can last 10–15 years or more with proper use.

| Inverter Type | Typical Lifespan | Maintenance Needs |

|---|---|---|

| High-Frequency | 5–8 years | Higher |

| Low-Frequency (Transformer) | 10–15 years | Low |

These inverters are less vulnerable to thermal stress, component aging, and surge-related damage—resulting in lower long-term costs for system owners and fewer returns or warranty claims for importers.

🌍 Why Importers and Distributors Prefer Transformer-Based Inverters

For solar companies and distributors in Africa, the Middle East, Southeast Asia, and Latin America, the benefits are clear:

🔩 Fewer failures = stronger reputation

📦 Lower replacement rate = reduced logistics cost

💬 Customer satisfaction = higher repeat sales

🛠️ OEM/ODM flexibility = branding advantage

📦 Recommended Applications

Rural homes and farms with deep well pumps

Cold storage facilities needing reliable refrigeration

Clinics, hospitals, and telecom systems

Industrial off-grid microgrids

✅ Final Thoughts

While high-frequency inverters may be smaller and cheaper, transformer-based low-frequency inverters deliver what really matters: reliability, longevity, and resilience under pressure.

If you’re an importer or solar solutions provider seeking inverter products that last longer, perform better, and build trust, low-frequency technology is your best investment.

📩 Call to Action

Looking for a reliable inverter partner?

Contact SWN Inverter for high-performance, transformer-based solutions tailored for your off-grid markets.

👉Contact Us:email:info@swnpower.com whatsapp:+86-15914572726